Fuel Life Cycle Analysis

Life Cycle Associates calculates life cycle greenhouse gas and criteria pollutant emissions from the production and use of fossil and alternative fuels. Our team of experts has over seventy years cumulative experience in handling a wide range of fuel life cycle analysis projects.

We can support you in:

Determining emissions of greenhouse gases, criteria pollutants, and toxics

Analysis of land use impacts

Net energy balance

Analysis of specific and novel fuel pathways

Fuel Certification under RFS 2, LCFS, RED, RSB

Customizations to established life cycle analysis models such as GREET and GHGenius

Development of custom user interfaces and other software tools

Economic modeling of displacement effects and co-products

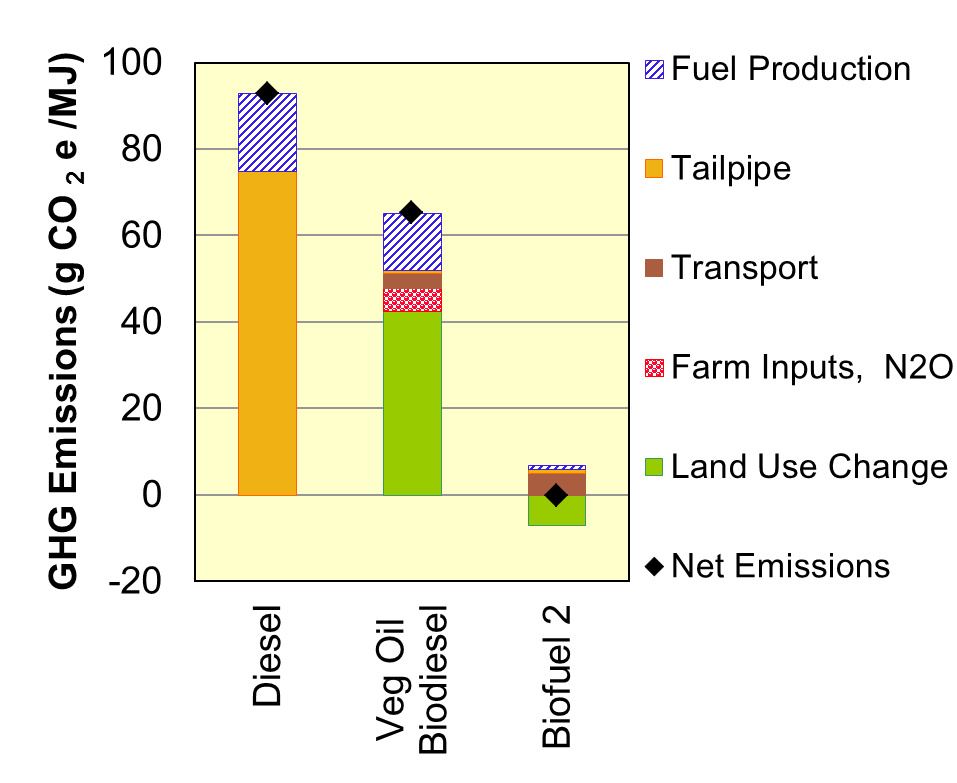

Fuel Cycle Analysis Chart

What is Fuel Life Cycle Analysis?

Fuel life cycle analysis (LCA) is a technique that allows you to quantify the potential impacts to the environment from all aspects of a fuel’s life; i.e. feedstock production, fuel processing, transport, and use. It also includes all the chemicals and energy that go into making a product, and what it takes to make those.

In order to apply for a pathway under the U.S. Renewable Fuel Standard or California’s Low Carbon Fuel Standard, you will need to perform an LCA on all of the greenhouse gas emissions generated by your fuel product. So what does this mean?

For biomass based fuels, the first step in production is farming of the biomass feedstock. This takes chemical and energy inputs, which have to be included. Next, the feedstock is transported to the production facility in trucks, rail cars, pipelines, etc. At the facility, energy inputs like natural gas and electricity are used to run the process, and chemical inputs like hydrogen or sodium hydroxide may also be used, depending on the production process. The finished fuel is transported to retail and then combusted in vehicles. All of these steps together comprise what is known in fuel LCA as a well-to-wheels (WTW) life cycle analysis, as shown in the image below.

Performing a life cycle analysis of your fuel allows you to calculate its carbon intensity, i.e. the amount of carbon emissions generated for each unit of fuel produced. This number can be compared to the carbon intensity of gasoline to show just how much less carbon is produced when vehicles use your biofuel instead of the petroleum alternative.

Additional Considerations

Seems pretty simple, right? It is! But in order to ensure that your LCA is accurate, there are a number of questions you’ll want to consider.

- Allocation: Does your process result in more than one product? If so, then you may need to allocate the impacts of your process between co-products based on energy content, mass, etc.

- Land use change: Does the growing of your feedstock crop indirectly cause land use changes? If so, these will need to be included in your LCA.

Questions

Do you have questions about fuel life cycle analysis for your specific business case?